Towards computer vision feedback for enhanced CNC machining

Por um escritor misterioso

Last updated 10 março 2025

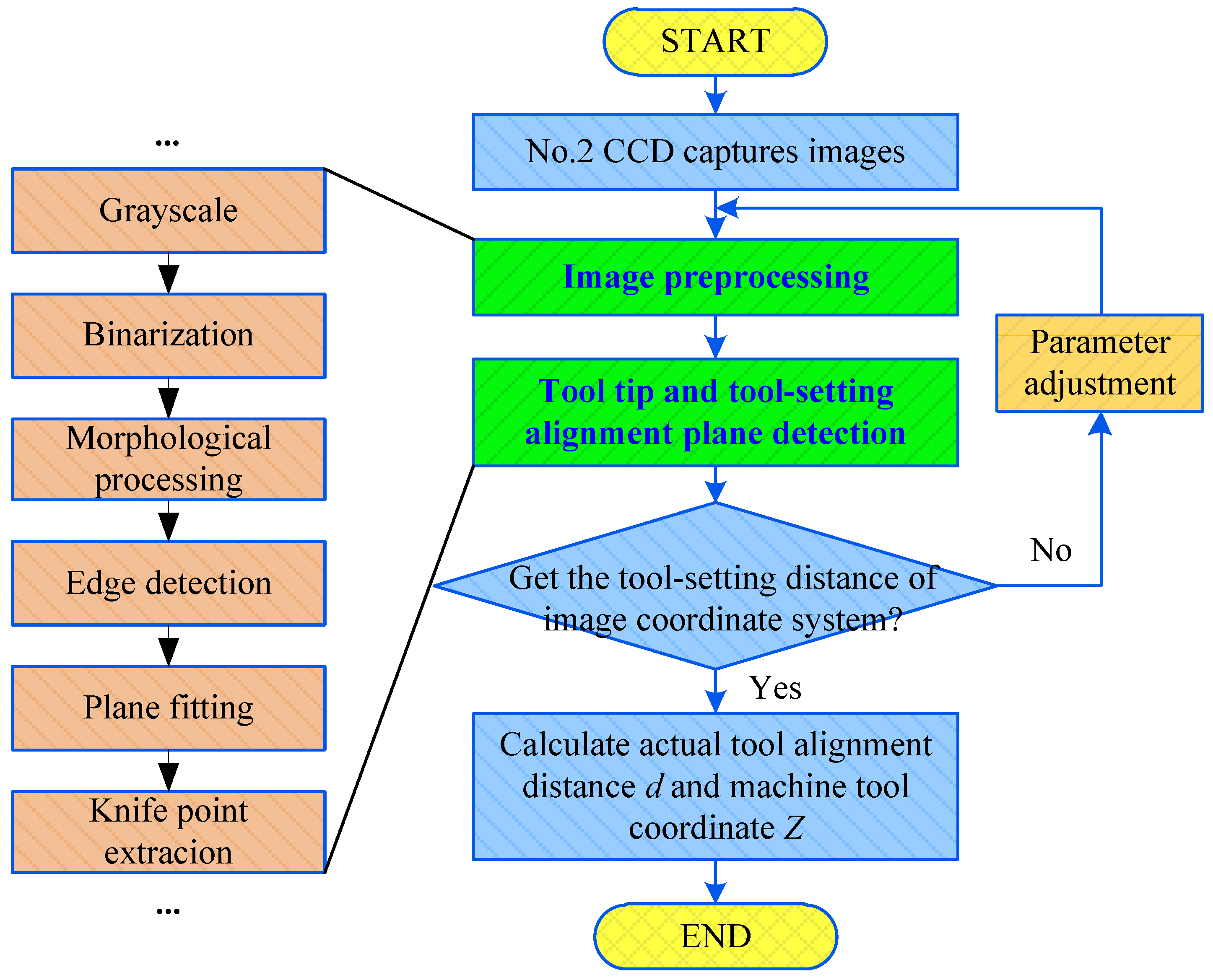

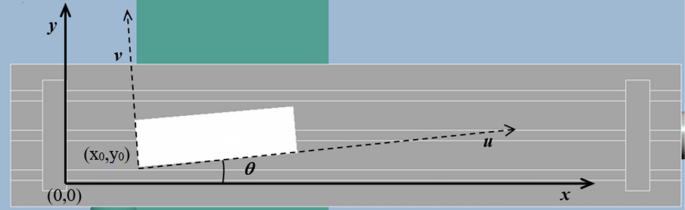

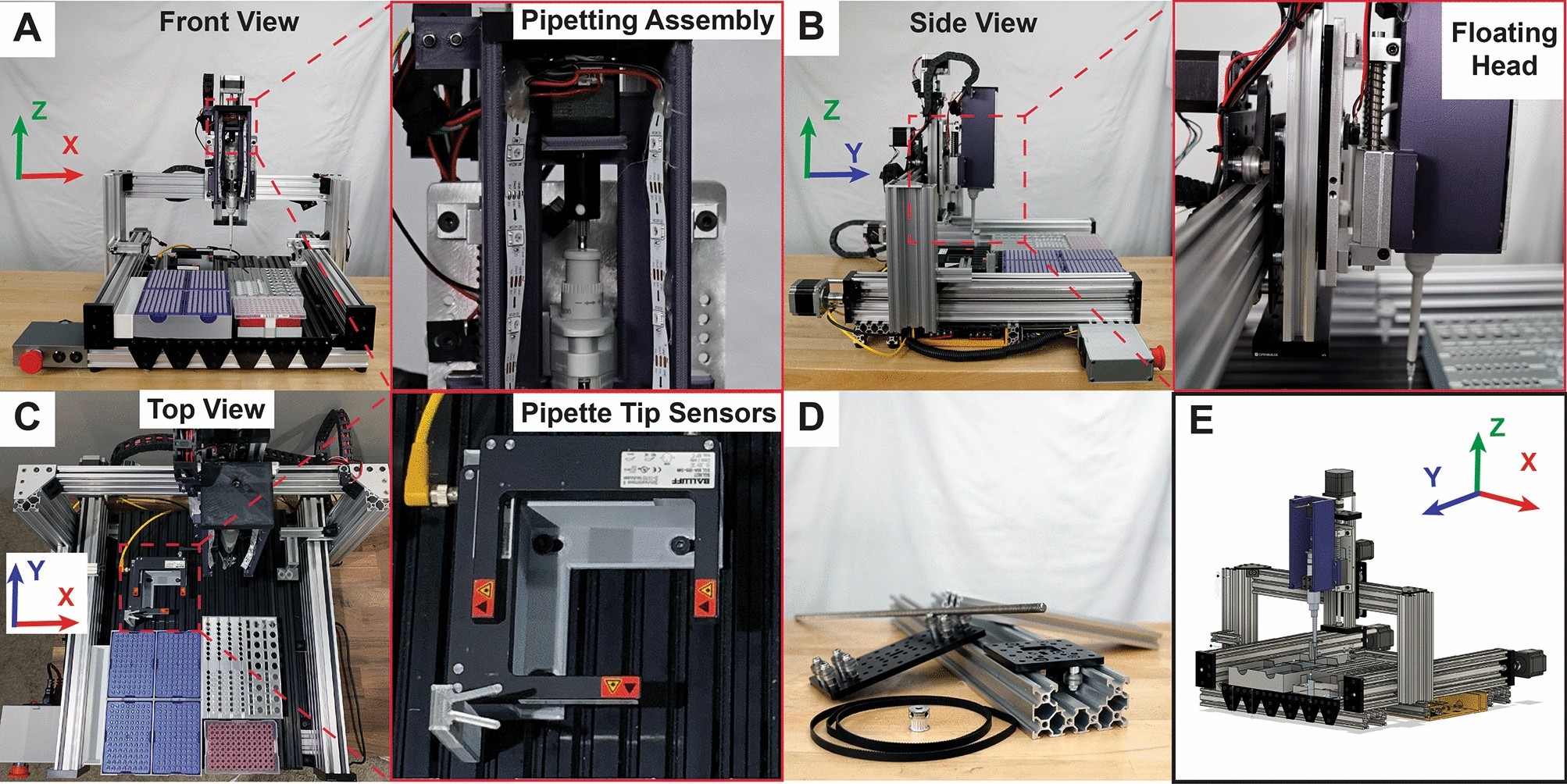

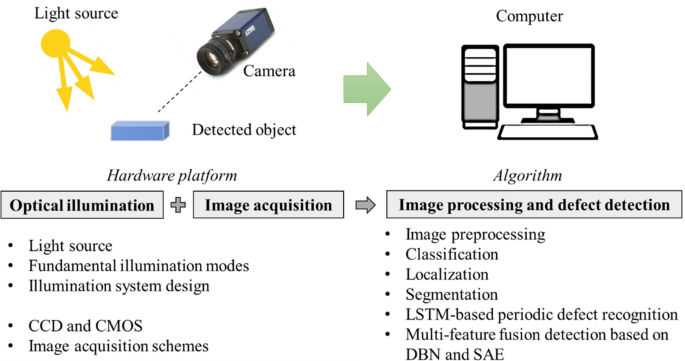

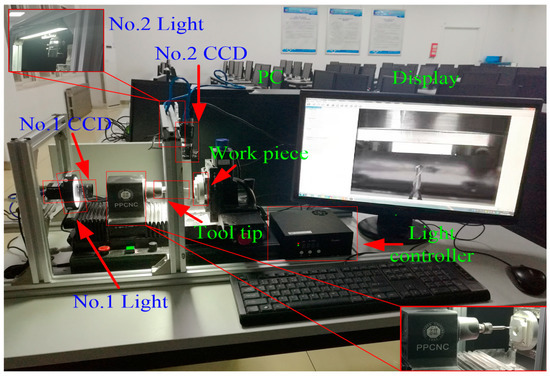

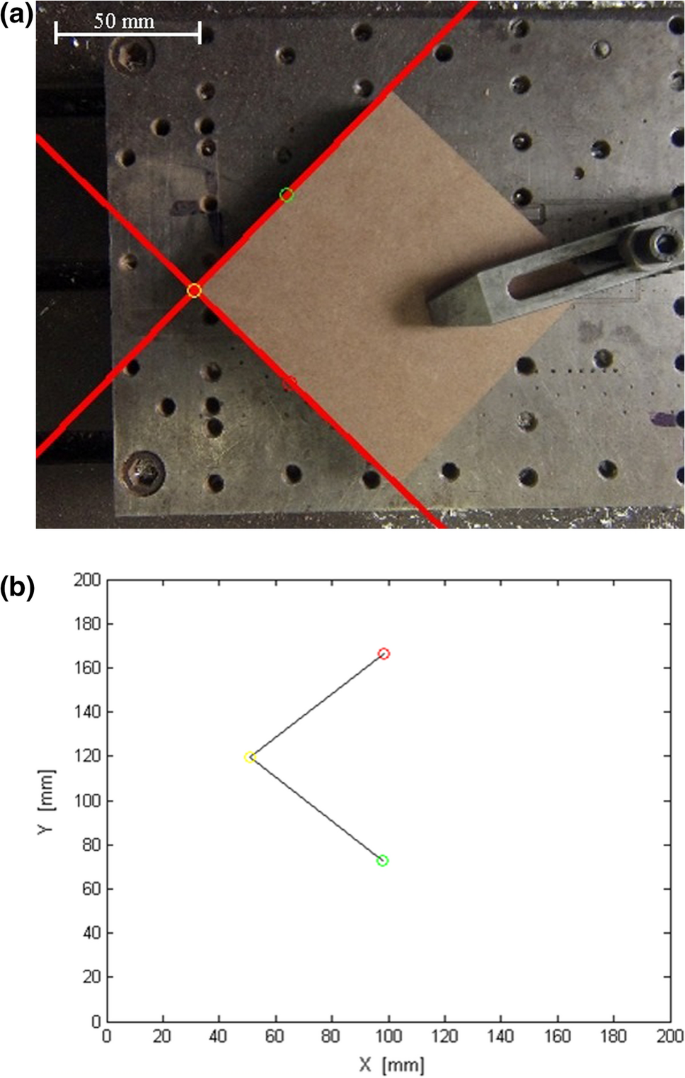

A vision-based sensing utility is proposed and developed to enhance the performance of CNC milling machines and to facilitate on-line monitoring and control, computer programs are developed to manipulate the source G-code file to enable real time integration of the gained feedback information. A vision-based sensing utility is proposed and developed to enhance the performance of CNC milling machines. Two cameras are attached to the machine spindle to provide visual information on work-piece surface quality while machining. This information is processed and processing outcome is used to improve the surface roughness of the machined part by adjusting the employed machining parameters. To facilitate on-line monitoring and control, computer programs are developed to manipulate the source G-code file in order to enable real time integration of the gained feedback information. The manipulated G-code program is then executed by the machine controller to allow adaptive control of the work-piece machining. The developed system automatically determines which camera is required to provide scene data for each step of tool path movement. Relative camera is then activated just as the machine completes the cutting of each tool path segment. Acquired vision data is processed to evaluate resulting surface roughness and accordingly a decision is made to either maintain the implied machining parameters or adjust their values to beneficially suit the machining task and result in better surface quality. The developed approach is tested and verified experimentally. Promising results are acquired that encourage further development towards full integration of CNC-vision systems.

Sensors, Free Full-Text

Development of a computer vision-based system for part referencing

Machine learning and artificial intelligence in CNC machine tools

5 Axis CNC Machining: Types, Applications, Benefits, and Design

Principles of computer-controlled linear motion applied to an open

ABBRobotics

State of the Art in Defect Detection Based on Machine Vision

Development of a computer vision-based system for part referencing

Sensors, Free Full-Text

Machine vision systems: 1D, 2D, and 3D

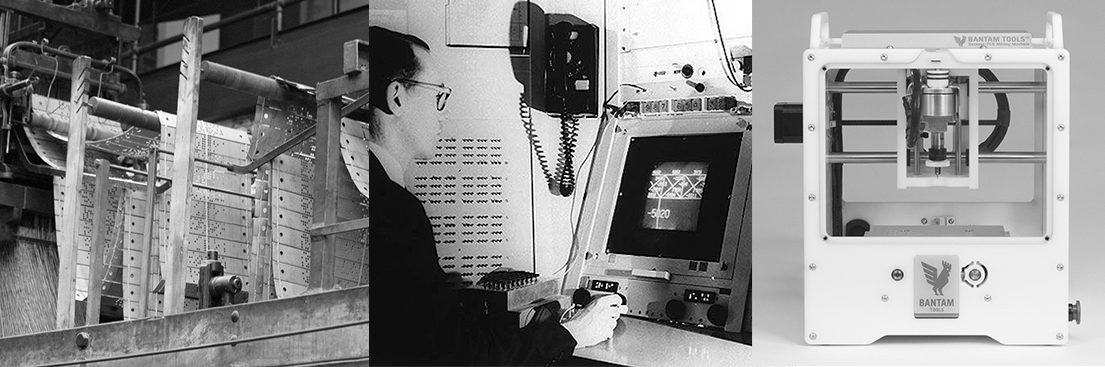

History of CNC Machining. Part 1: The People, Stories, and…

Development of a computer vision-based system for part referencing

Machine learning and artificial intelligence in CNC machine tools

Towards computer vision feedback for enhanced CNC machining

Recomendado para você

-

Knocking the dust off. Felt so good to drive it again #diesel10 março 2025

-

3 Row Radiator For 1966-79 Ford Bronco Truck F100 F150 F250 F35010 março 2025

3 Row Radiator For 1966-79 Ford Bronco Truck F100 F150 F250 F35010 março 2025 -

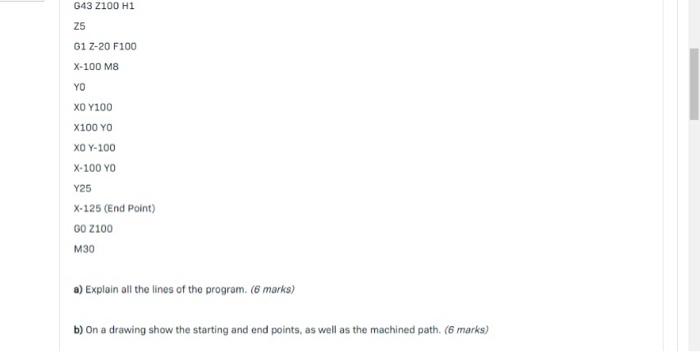

Solved G43 Z100 H1 25 G1 Z-20 F100 X-100 M8 YO XO Y100 X10010 março 2025

-

New US Keyboard for HP Pavilion 17t-f100 17t-f100 17z10 março 2025

New US Keyboard for HP Pavilion 17t-f100 17t-f100 17z10 março 2025 -

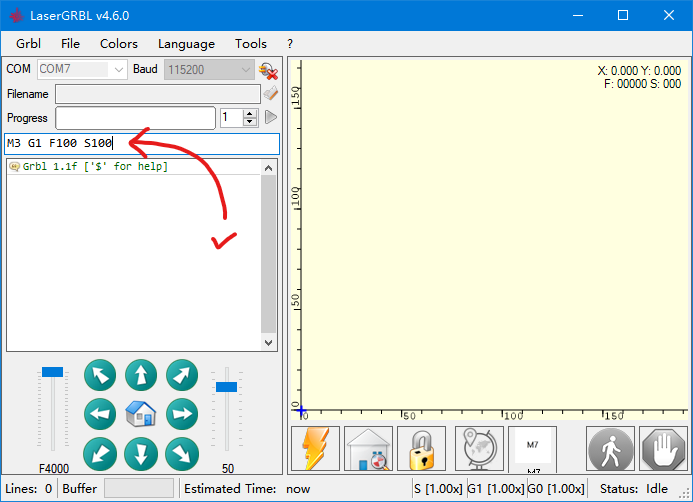

How to Test Laser at GRBL – NEJE10 março 2025

How to Test Laser at GRBL – NEJE10 março 2025 -

![LAST PRICE]PC with TV-box i5-6400/8G DDR4 Ram/New 256Gb NVME SSD](https://images.craigslist.org/00C0C_6MdecwLenMC_0CI0pI_600x450.jpg) LAST PRICE]PC with TV-box i5-6400/8G DDR4 Ram/New 256Gb NVME SSD10 março 2025

LAST PRICE]PC with TV-box i5-6400/8G DDR4 Ram/New 256Gb NVME SSD10 março 2025 -

Text To CNC - Apps on Google Play10 março 2025

-

Nikon F100 Film Camera Sample Photos and Specifications10 março 2025

Nikon F100 Film Camera Sample Photos and Specifications10 março 2025 -

Cutting rules for small holes for plasma cutters. - Autodesk10 março 2025

-

can I change default fontsize?10 março 2025

can I change default fontsize?10 março 2025

você pode gostar

-

Hans vs. Dina (Apr 2022) : r/chess10 março 2025

Hans vs. Dina (Apr 2022) : r/chess10 março 2025 -

Pokemon Xy Anime Poster – My Hot Posters10 março 2025

Pokemon Xy Anime Poster – My Hot Posters10 março 2025 -

Epic games phone hi-res stock photography and images - Alamy10 março 2025

Epic games phone hi-res stock photography and images - Alamy10 março 2025 -

Atingi meu recorde no subway surf, deposite seu dane-se Novo10 março 2025

Atingi meu recorde no subway surf, deposite seu dane-se Novo10 março 2025 -

Gg wp Good Game well played ggwp victory in videogames Esports Poster for Sale by ZooOfArt10 março 2025

Gg wp Good Game well played ggwp victory in videogames Esports Poster for Sale by ZooOfArt10 março 2025 -

![A Guide To The Hunger Games Books In Order [Infographic] - Venngage](https://venngage-wordpress.s3.amazonaws.com/uploads/2023/11/hunger-games-books-in-order-blogheader-1.png) A Guide To The Hunger Games Books In Order [Infographic] - Venngage10 março 2025

A Guide To The Hunger Games Books In Order [Infographic] - Venngage10 março 2025 -

Code Vein - Review10 março 2025

Code Vein - Review10 março 2025 -

10 Anime To Watch If You Liked Monster10 março 2025

10 Anime To Watch If You Liked Monster10 março 2025 -

Stanford turns a DeLorean into a drifting, driverless car10 março 2025

Stanford turns a DeLorean into a drifting, driverless car10 março 2025 -

ALL 14 SECRET BAKUGO GEM CODES IN ANIME DIMENSIONS! Roblox *USE10 março 2025

ALL 14 SECRET BAKUGO GEM CODES IN ANIME DIMENSIONS! Roblox *USE10 março 2025